SHARPE MIXERS INC

PRODUCT DISPLAY

Always put customers first, pay attention to customer needs

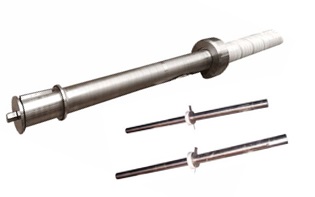

Shaft and Bearing

Publish time 2018-11-26 10:54

NO1 Shaft

The shaft of Shrpe Mixers is made of monolithic alloy.Mixer shafts are required to transmit the power from the mixer drive to the impeller(s). With the transmission of this power, the shaft must handle the loads occurring including the transmission of torque, overhung moment due to hydraulic forces, and thrust. The shaft must also be designed to be stiff enough to limit vibration and deflection to acceptable levels. Mixer shafts are commonly built from solid round bar, hollow shafting, or a combination of both.

The shaft of Shrpe Mixers is made of monolithic alloy.Mixer shafts are required to transmit the power from the mixer drive to the impeller(s). With the transmission of this power, the shaft must handle the loads occurring including the transmission of torque, overhung moment due to hydraulic forces, and thrust. The shaft must also be designed to be stiff enough to limit vibration and deflection to acceptable levels. Mixer shafts are commonly built from solid round bar, hollow shafting, or a combination of both.

The strength of a shaft is determined by the section modulus of the shaft. For a given section modulus, a hollow shaft will be larger in outside diameter, but will weigh less than the equivalent solid shaft.

Solid shafting has been the most common choice among mixer manufacturers for many years because of availability, ease of construction and the fact that many impeller hubs require a key to transmit torque. Many mixer manufacturers stock one-piece impeller hub castings to which they bolt blades. These hubs slide onto the shaft from one end and are held in place with a key and set-screw. Since the required mating keyway would cut through a hollow shaft, a solid shaft is required. This design and the required inventory is a commitment to solid shafting by default. The disadvantage of keyed one-piece hubs is that they can be difficult to remove from the shaft, steady bearings must be disassembled to allow clearance for impeller removal, and the impeller will usually weigh more due to the required thickness at the bolted blade attachment area

Solid shafting has been the most common choice among mixer manufacturers for many years because of availability, ease of construction and the fact that many impeller hubs require a key to transmit torque. Many mixer manufacturers stock one-piece impeller hub castings to which they bolt blades. These hubs slide onto the shaft from one end and are held in place with a key and set-screw. Since the required mating keyway would cut through a hollow shaft, a solid shaft is required. This design and the required inventory is a commitment to solid shafting by default. The disadvantage of keyed one-piece hubs is that they can be difficult to remove from the shaft, steady bearings must be disassembled to allow clearance for impeller removal, and the impeller will usually weigh more due to the required thickness at the bolted blade attachment area

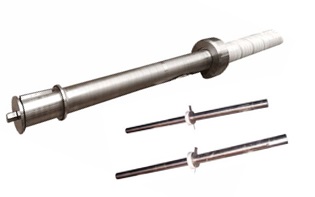

NO2 Bearing

Shrpe Mixers bearings are special flanged bearing components customized by Dodge and Timken Bearing Company. Tapered roller bearings are used to support both radial and axial loads. Double-row tapered roller bearings can bear bidirectional axial loads.

This is more convenient for parts replacement and maintenance costs.。

The strength of a shaft is determined by the section modulus of the shaft. For a given section modulus, a hollow shaft will be larger in outside diameter, but will weigh less than the equivalent solid shaft.

NO2 Bearing

This is more convenient for parts replacement and maintenance costs.。

CONTACT US

Address:228 PARKAVE S#79525 New York, USA NY 10003

Tel:323-9088554

Fax:626-4530409

E-mail:sales@sharpe-mixers.com

323-9088554

Copyright Sharpe Mixers 2018 | All rights reserved | Privacy Policy Proudly powered by Webrunner